Stainless Steel Suppliers

Unogona here solder Stainless simbi?

Soldering Stainless simbi inogona kuita sebasa rakaoma, asi hazvigoneke. Fungidzira uri mushori wezvishongo, une basa rekugadzirisa imba yenhaka yemhuri inodiwa yakagadzirwa nesimbi isina tsvina. Iwe unoziva kuti welding haisi sarudzo, asi mutengi anoda kuti chidimbu chitaridzike sechakanaka. Unoita nezvei? Iwe unotendeukira kune soldering.

Newewo unogona solder Stainless simbi?

Hongu, kutengesa simbi isina tsvina kwakaoma nekuti ine nzvimbo yakakwira yekunyungudika uye haibvumire solder. Welding kana brazing inowanzo shandiswa pachinzvimbo.

Nematurusi akakodzera uye matekiniki, Welding kana brazing inogona kuve nzira yakanaka yekubatanidza simbi isina kukuvadza pasina kukuvadza chidimbu. Muchikamu chino, tichaongorora ins uye kunze kwekutengesa simbi isina tsvina, uye tokuratidza kuti zvinokwanisika kugadzira chisungo chakasimba uye chakanaka chichagara kwemakore anotevera. Saka, kana iwe uchida kuziva kana iwe uchigona solder Stainless simbi, ramba uchiverenga.

Ndeapi marudzi akasiyana enzira dzekutengesa simbi isina tsvina?

Pane nzira dzinoverengeka dzekutengesa simbi isina tsvina, imwe neimwe iine zvayakanakira nezvayakaipira. Nzira dzinonyanyozivikanwa dzinosanganisira:

Silver brazing:

Iyi nzira inoshandisa sirivheri alloy kugadzira chisungo chakasimba, chakasimba pakati pezvidimbu zvesimbi.TIG welding:

Tungsten Inert Gasi (TIG) welding inogona zvakare kushandiswa kushambadzira simbi isina tsvina. Iyi nzira inoshandisa tungsten electrode kupisa simbi uye tsvimbo yekuzadza kubatanidza zvidimbu.MIG welding:

Metal Inert Gasi (MIG) welding inogona zvakare kushandiswa kushambadzira simbi isina tsvina. Iyi nzira inoshandisa wire feed uye inert gasi kugadzira chisungo chakasimba pakati pezvidimbu.Resistance welding:

Iyi nzira inoshandisa kupikisa kwemagetsi kupisa simbi isina tsvina uye kugadzira chisungo pakati pezvidimbu.Laser welding:

Iyi nzira inoshandisa yakakwirira-simba laser danda kupisa uye kujoina zvimedu zvesimbi isina tsvina.

Sarudzo yenzira inotsamira pane chaiyo application uye zvinodikanwa zvekusimba, kusimba, uye kusadzivirirwa nekuora. Zvakakosha kusarudza nzira iyo ichapa chisungo chakasimba uye chakavimbika kune chinangwa chekushandiswa.

Imhandoi ye solder inofanira kushandiswa kune Stainless simbi?

Paunenge uchitengesa simbi isina tsvina, zvakakosha kusarudza mhando yakakodzera ye solder. Kazhinji, vatengesi vane yakakwira sirivheri yemukati vanokurudzirwa nekuti ivo vanopa zvirinani kusimba kwekubatanidza uye kusimba kwekuora. Yakajairika solder alloys yesimbi isina tsvina anosanganisira esirivha-based solders, akadai seaya ane sirivheri, mhangura, uye zinc.

Zvakakoshawo kushandisa flux yakanyatsogadzirirwa simbi isina tsvina. Iyo flux inobatsira kudzivirira oxidation panguva yekushambadzira uye inosimudzira kunamatira pakati peiyo solder uye simbi isina tsvina. Mamwe anokurudzirwa mafambiro ekutengesa simbi isina tsvina anosanganisira ayo ane boron, zinc chloride, kana ammonium chloride.

Zvakakosha kutevedzera mirairo yemugadziri wezvose zviri zviviri solder uye flux kuve nechokwadi chekubatana kwakakodzera uye kudzivirira chero zvingangoitika nyaya nekuora kana simba. Pamusoro pezvo, zvakakosha kuchenesa nemazvo uye kugadzirira iyo simbi isina tsvina isati yaiswa solder kuti ive nechokwadi chakasimba uye chinogara chisungo.

Zvakaoma here solder Stainless simbi zvichienzaniswa nezvimwe zvinhu?

Hongu, kushambadzira simbi isina tsvina kunogona kunetsa kupfuura zvimwe zvinhu nekuda kwekukwirira kwayo kwekushisa uye kuderera kwekuwedzera kwekuwedzera kwemafuta.

Inoda tembiricha yepamusoro uye yakasarudzika mhando yekuyerera kubvisa chromium oxide layer inodzivirira simbi isina tsvina kubva mukuora. Pamusoro pezvo, simbi isina tsvina ine tsika yekumonereka uye kumonyoroka kana yaiswa pakupisa, zvichiita kuti zvive zvakakosha kushandisa nzira dzakakodzera uye midziyo kudzivirira kukanganisa.

Zvisinei, nekugadzirira kwakakodzera, midziyo yakakodzera uye zvinhu, uye unyanzvi hwakanaka, kutengesa simbi isina tsvina inogona kubudirira kubudirira. Vane ruzivo welders uye vashandi vesimbi vanowanzokwanisa kuwana mhedzisiro yakanaka nesimbi isina simbi solder.

Simbi isina tsvina inogona kutengeswa pasina kushandisa flux?

Yes, kuchembera simbi isina tsvina kunogoneka, asi hazvikurudzirwe.

Flux inobatsira kubvisa chero ma oxides kana zvinosvibisa pamusoro pesimbi isina tsvina, zvichiita kuti solder ibatane zvakanaka. Pasina flux, solder inogona kusanamatira zvakanaka, zvichiita kuti zvive zvisina simba kana kuti zvisina kukwana. Uyezve, pasina flux, iyo solder process inogona kutora nguva yakareba, uye mikana yekupisa kana kukuvadza simbi isina tsvina inowedzera. Zvakanakisa kushandisa flux yakakodzera yesimbi isina simbi solder kuti ive nechokwadi chemhedzisiro. Rudzi rwekuyerera rinoshandiswa zvinoenderana neiyo solder nzira uye chaiyo Stainless simbi alloy iri kutengeswa. Kushandisa flux isiriyo kunogona kutungamirira kuhutano husina kunaka hwekubatana kana kunyange kuora nekufamba kwenguva. Naizvozvo, zvakakosha kubvunzana nenyanzvi kana kutarisa kune nhungamiro yemugadziri kuti uone kuti iyo chaiyo flux inoshandiswa pakuita solder.

Unogona kutengesa mamakisi akasiyana esimbi isina tsvina pamwechete?

Kwete. Kusondha magiredhi akasiyana-siyana esimbi isina tsvina pamwe chete kunogona kunetsa nekuda kwekusiyana-siyana kwehuwandu hwealloy uye maumbirwo.Zvinokurudzirwa kudzivirira kubatanidza magiredhi akasiyana esimbi isina tsvina, sezvo zvichigona kuguma nekuora uye kukanganisa michina.

Zvisinei, kana soldering ichidiwa, zvakakosha kushandisa solder inopindirana nemhando mbiri dzesimbi isina tsvina uye kunyatsofungisisa kugadzirwa kwekubatana uye kugadzirira kuve nechokwadi chekubatana kwakasimba uye kwakasimba. Welding kana brazing inogona kunge iri nani sarudzo dzekujoinha magiredhi akasiyana esimbi isina tsvina. Zvinogara zvichikurudzirwa kubvunza ane hunyanzvi hwemetallurgist kana welding engineer usati waedza kutengesa magiredhi akasiyana esimbi isina tsvina pamwechete.

Ndeipi tembiricha inodiwa solder Stainless simbi?

Tembiricha inodiwa solder simbi isina tsvina zvinoenderana nerudzi rwe solder uye flux iri kushandiswa. Kazhinji, tembiricha iri pakati pe600 ne800 madhigirii Fahrenheit inodiwa kunyungudutsa solder uye kugadzira chisungo nesimbi isina tsvina. Zvakakosha kucherechedza kuti kupisa kwesimbi isina tsvina kunogona kukonzera kukanganisa kwezvinhu zvayo uye kutungamirira pakuumbwa kwenzvimbo dzinopisa.

Pamusoro pezvo, zvakakosha kushandisa simbi yekunyungudutsa kana torch ine yakanaka tembiricha kutonga kudzivirira kupisa uye kuve nechokwadi chekudziya kunoenderana kweiyo solder joint. Inokurudzirwawo kushandisa chiratidzo chekushisa senge thermocouple kutarisa kudziya kwejoint panguva yekushambadzira.

Pakazara, tembiricha inodiwa pakusunga simbi isina tsvina yakakwira kupfuura iyo inodiwa pakutengesa zvimwe zvinhu zvakaita semhangura kana ndarira, uye zvakakosha kutevera nzira dzakakodzera dzekutengesa kuti uwane mubatanidzwa wakasimba uye wakasimba.

Pane here matanho ekuchengetedza ekutora pakusodha simbi isina tsvina?

Yes, there pane akati wandei ekuchengetedza edziviriro aunofanira kutora kana uchitengesa Stainless simbi. Chokutanga uye chakakosha, zvakakosha kuti shanda munzvimbo ine mhepo yakanaka kudzivirira kufema chero utsi hunogadzirwa panguva yekushongedza. Zvakakoshawo kuti pfeka giya rekudzivirira, semagirovhosi uye magirazi ekuchengetedza, kudzivirira kupisa uye kuratidzwa kune solder flux.

Mukuwedzera, zvinokosha kuti shandisa iron soldering ine tembiricha yekudzora kudzivisa kupisa simbi isina tsvina, iyo inogona kukonzera kushanduka uye kuderedza zvinhu. Inokurudzirwa zvakare kuti shandisa solder paste kana flux yakanyatsogadzirirwa simbi isina tsvina kuve nechokwadi chisungo chakasimba uye kudzivirira kukanganisa kwezvinhu.

Pakupedzisira, zvakakosha kuti tevera nzira dzakafanira dzekurasa chero tsvina inogadzirwa panguva yekugadzira soldering, seyakashandiswa solder flux uye zvimedu zve solder. Zvinhu izvi zvinogona kuva nengozi kune zvakatipoteredza kana zvikasaraswa zvakanaka.

Ko ukobvu hwesimbi isina tsvina hunokanganisa sei hurongwa hwekusodha?

Ukobvu hwesimbi isina tsvina hunogona kukanganisa kushandiswa kwekutengesa nenzira shomanana. Simbi yakakora inoda kupisa kwakawanda kuti ishandiswe kuitira kuti solder inyatsoyerera uye ibatane nesimbi. Izvi zvinogona kuita kuti hurongwa huve hwakaoma, sezvo simbi inogona kupeta kana kukuvadzwa kana kupisa kwakawanda kuchiiswa. Pamusoro pezvo, simbi yakakora inogona kuda nguva yakareba yekudziya, iyo inogona kuwedzera njodzi yekupisa kwe solder kana kupisa kunopisa nekukasira.

Nekune rimwe divi, simbi yakatetepa inogona kuve nyore kuputika kana kunyungudika kana kupisa kwakawanda kuchiiswa. Zvinogonawo kuva zvakanyanya kuoma kugadzira chisungo chakasimba pakati pe solder nesimbi kana simbi yakanyanya kuonda.

Naizvozvo, zvakakosha kufunga nezvekukora kwesimbi isina tsvina paunenge uchironga kugadzirwa kwekutengesa. Kudzora tembiricha kwakakodzera uye hunyanzvi hwakakosha kuti uwane chisungo chakabudirira uye chakasimba pakati pe solder nesimbi, zvisinei nekukora kwayo.

Ndeapi mamwe maapplication akajairika apo soldering inoshandiswa pasimbi isina tsvina?

Soldering inowanzoshandiswa mumashandisirwo akasiyana-siyana apo simbi isina tsvina inobatanidzwa. Mimwe mienzaniso yakajairika inosanganisira kugadzira zvishongo, kugadzira zvemagetsi, pombi dzemvura, uye kugadzirisa mota.

Mukugadzira zvishongo, solder inoshandiswa kubatanidza zvikamu zvakasiyana-siyana zvechidimbu, senge clasps nemaketani. Mumusangano wemagetsi, soldering inoshandiswa kubatanidza zvikamu kumapuranga edunhu akadhindwa. Mukugadzira pombi, soldering inoshandiswa kubatanidza mapaipi emhangura kune zvigadzirwa zvakagadzirwa nesimbi isina tsvina. Mukugadzirisa motokari, soldering inoshandiswa kugadzirisa maitirwo emhepo uye zvimwe zvikamu zvakagadzirwa nesimbi isina tsvina.

Soldering inopa nzira inodhura uye inobudirira yekubatanidza zvinhu zvesimbi isina tsvina, kunyanya mumamiriro ezvinhu apo welding inogona kusashanda kana kudiwa. Zvisinei, zvakakosha kuti usarudze nzira yakakodzera yekutengesa uye zvinhu zvekushandiswa kwakananga kuti ive nechokwadi chekubatana kwakasimba uye kwakasimba. Pamusoro pezvo, zvidziviriro zvekuchengetedza zvinofanirwa kutorwa kuti zvidzivirire pakupisa uye utsi hunogadzirwa panguva yekushongedza.

mhedziso

Mukupedzisa, soldering inogona kuva mhinduro inoshanda yekubatanidza kana kugadzirisa simbi isina tsvina, asi inoda maitiro chaiwo uye zvinhu. Kune marudzi akasiyana-siyana ekugadzirisa nzira dzesimbi isina tsvina, uye nzira yakakodzera inobva pane chaiyo inoshandiswa uye rudzi rwesimbi isina tsvina iri kushandiswa. Paunenge uchitengesa simbi isina tsvina, zvakakosha kushandisa iyo chaiyo solder uye flux kuve nechokwadi chakasimba uye chinogara chisungo. Uyezve, matanho ekuchengetedza akakodzera anofanirwa kutorwa, uye ukobvu hwesimbi isina tsvina inogona kukanganisa nzira yekusimbisa. Nepo soldering inogona kuva mhinduro inobatsira, inogona kunge isiri iyo yakanakisa kana yekusingaperi sarudzo yekugadzirisa simbi isina tsvina. Zvimwe zvakajairika kunyorera simbi isina tsvina zvinosanganisira maHVAC masisitimu, michina yekurapa, uye zvinhu zvemuchadenga. Pakazara, iyo yakabudirira solder yesimbi isina tsvina inoda kunyatsotarisisa kune zvakadzama uye nzira yakakodzera yekusimbisa chisungo chakasimba uye chakavimbika.

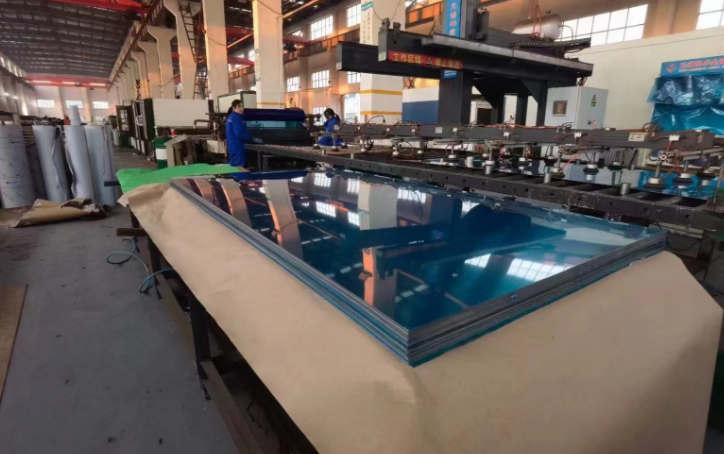

Kana iwe uchida kutsvaga akavimbika Stainless simbi mutengesi, tinokupa zano kuti ufunge Sino Stainless Steel. Semutengesi anotungamira wezvigadzirwa zvesimbi isina tsvina, Sino Stainless Steel inopa vatengi simbi isina tsvina, Stainless simbi coils, mahwendefa esimbi asina tsvina, machira esimbi asina tsvina, simbi isina tsvina, uye waya dzesimbi dzisina tsvina pamutengo wakakwikwidza zvikuru.

Tora Quote Free

Zviri Content

Related Posts

What is ASTM standard for SS round bar?

Stainless steel (SS) round bars occupy a pivotal position due to their widespread applications in various industries. The ASTM standard for SS round bar is

Chii mutengo weSS round bar?

Mutengo weSS round bar inyaya yakaoma, inopesvedzerwa nezvinhu zvakasiyana-siyana kubva kumitengo yezvinhu, magadzirirwo ekugadzira, kudiwa kwemusika, uye kupa.

Ndeupi musiyano uripo pakati pe strip ne sheet metal?

Munzvimbo yesimbi uye zvigadzirwa zveinjiniya, strip uye sheet simbi mazwi maviri anowanzoshandiswa zvakasiyana, asi muchokwadi, iwo anayo.

Ndeupi mutengo we410 Stainless steel sheet?

Munzvimbo yesimbi uye sainzi yemidziyo, simbi isina tsvina inogara pachinzvimbo chakakosha nekuda kwekusarudzika kwekuramba kwecorrosion uye kusimba. Pakati pe

Ndeupi musiyano uripo pakati pepepa coil nendiro?

Senyanzvi ine ruzivo mumunda wezvigadzirwa zvesimbi kubva kuSino Stainless Steel, ndasangana nemhando dzakawanda dzesimbi mafomu, imwe neimwe ichishanda yayo.

:+86-18621535697

:+86-18621535697  :export81@huaxia-intl.com

:export81@huaxia-intl.com